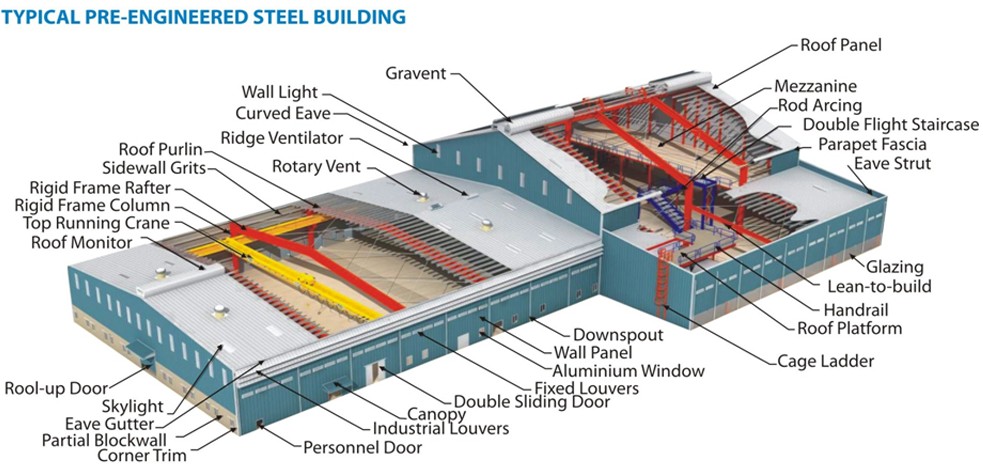

Steel structure building is formed by the main framework through linking up the H beam, C purline, Z purline steel components. Roof and wall using a variety of panels together with other components such as windows and doors. The steel building has the advantages of wide span, high strength, light weight, low cost, temperature protection, save energy, beautiful appearance, short construction time, good effect of insulation, long using life, space-efficient, good seismic performance, flexible layout, etc.

The Steel Structure Workshop is safe and reliable, and it is easy to assemble and disassemble. It is an ideal choice for industrial and commercial buildings, such as warehouses, workshops, hangars, supermarkets, offices and poultry feeding.

1. Easy to assemble

The steel components arriving at the construction site are all prefabricated. During the construction process, the installation work needs to layout each structure and erect it according to the installation drawing.

2. Reasonable cost

The steel structure building is light in weight, reducing the basic cost, and the construction speed is fast. It can be completed and put into production as soon as possible. The overall economic benefits are much better than that of the concrete structure

3. Simple construction, short construction period

The production and installation of steel structure usually involve processing all required components in the factory and then transporting to the construction site to assemble. So the construction period is greatly shortened.

4. Energy-saving and environmentally friendly

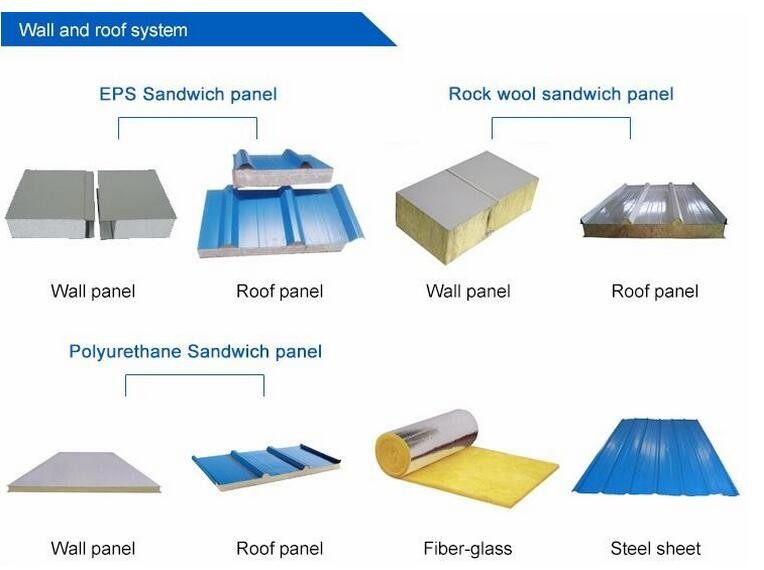

The corrugated color steel sheet and sandwich panels used in the prefab steel structure workshop are all energy-saving materials. The steel structure also adopts dry construction during the construction process to avoid dust and environmental pollution caused by concrete construction

| Attribute | Value |

|---|---|

| Material | Q355B/ Q235B Steel |

| Application Fields | Warehouse, Workshop, Hangar, Supermarkets, Office, Poultry Feeding |

| Structure | Steel Structure |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Drawing design | AutoCAD,PKPM,MTS,3D3S, Tarch, Tekla Structures |

| Insulation | Optional |

| Column and Beam | Hot Rolled/Welded H-Section Steel |

| Purlin | C Section/Z Section Steel |

| Downpipe | UPVC |

| Door | Rolled Up Door/Sliding Door |

Product Installation

With our top-notch installation support, you can rest assured that setting up your workshop will be a breeze. We provide detailed installation drawings and videos to guide you every step of the way. And if you need extra assistance, our dedicated staff and engineers are ready to be on-site to personally guide you through the process.

But that's not all! Our products are designed with convenience in mind. Loading and unloading them is a piece of cake. You can easily use a crane at the destination, and with just two people, you can unload the entire workshop in under half an hour. And don't worry about damaging the packaging - we guarantee it will remain intact!

When it comes to quality, we don't compromise. Our Customized Modern Space Frame Building Prefab Steel Structure Workshop is built to last. With a 50-year warranty and lifelong responsibility for after-sales service, you can trust that you're investing in a product that will stand the test of time.

Qualification certificates:

![]()

Packaging Details

1. Steel structure components will be in nude packaging with proper protection.

2. Sandwich panels will be packed with plastic film.

3. Doors and windows will be packed with bubble plastic.

4. Bolts and other accessories will be packed in wood boxes.